Search for information

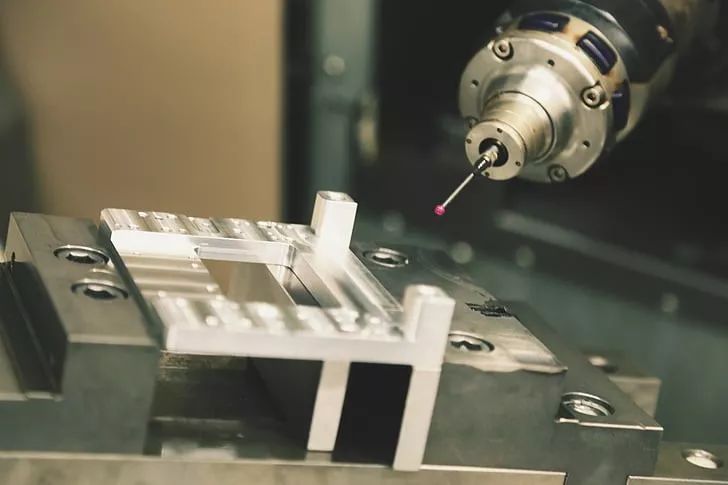

The Triumvirate of Ultra-Precision Machine Tools and Materials Science: Japan, Germany, and SwitzerlandUltra-precision machine tools and materials science form the bedrock of modern industry, and three nations—Japan, Germany, and Switzerland—dominate these critical sectors. Among them, Japan has established an unparalleled lead, blending technological innovation with meticulous engineering to set global standards.

May 19, 2025, 5:00 pm EDT

Source: Images from the Internet, if there is any infringement, please contact the removal of

Gastronomic Delights of Southern California: A Selection of Top Eateries

Gastronomic Delights of Southern California: A Selection of Top Eateriesmore

IOC's Efforts to Minimize Olympics' Carbon Footprint

The Olympic Games bring together athletes and spectators from across the globe, showcasing human potential, resilience, and a sense of unity unparalleled by other sporting events. To ensure the Games are held in the most efficient and responsible manner, the International Olympic Committee (IOC)'s Olympic Agenda mandates that hosts create a lasting positive impact on the host location while minimizing environmental harm. Central to this goal is the reduction of the carbon footprint associated with the Olympics.more

MLB Players' Participation in 2028 LA Olympics Remains Uncertain

The preparations for the return of baseball to the 2028 Los Angeles Olympics are underway, but a key issue remains unresolved: whether Major League Baseball (MLB) players will participate. Casey Wasserman, the president of the Los Angeles 2028 Olympic Organizing Committee, has started to clear the obstacles for the highly - anticipated return of baseball. Dodger Stadium has been chosen as the venue, but the big question of whether MLB stars will play is still up in the air.more

Los Angeles Food Highlights: Follow These 4 Signature Dishes and Avoid the Pitfalls!

Los Angeles Food Highlights: Follow These 4 Signature Dishes and Avoid the Pitfalls!more

Three Breathtaking Natural Destinations Around the World

Three Breathtaking Natural Destinations Around the Worldmore

China's Inaugural AI - Driven Robot Games Kick Off in Wuxi

China's first - ever AI - driven robot games have opened in Wuxi, a city in eastern China near Shanghai. These games mark a significant step as AI emerges from the laboratory to face the most human - like physical challenge: competition.more

Squash's Long-Awaited Olympic Debut at LA 2028 Olympics to Be Relatively Modest

Squash's Long-Awaited Olympic Debut at LA 2028 Olympics to Be Relatively Modestmore

The $8 million Super Bowl ad, sports brands “sky-high bet” worth it?

The $8 million Super Bowl ad, sports brands “sky-high bet” worth it?more